I searched and searched the internet trying to find advice on how to darken brown leather shoes but could only find advice for leather shoes. These shoes are not leather. Since I have a solution, here it is, internet.

First of all, I bought these shoes for my DragonCon steampunk owl outfit. They were on sale and I like them, but they were more tan than brown and I wanted them darker. So I removed the laces and got a tin of brown Kiwi shoe polish.

I didn't use any kind of fancy shoe cloth, just a paper towel. It worked just fine. I spread a layer on the "leather" parts of the shoe (I think they're polyester) and was pleased that it acted just like leather. The polish soaked into the grain and darkened immediately.

I did two coats, then did the other shoe. The lighting in this picture isn't great, but hopefully you can see the difference in the darker rear shoe and the lighter fore shoe that I hadn't yet worked on. They darkened a bit more overnight too, I guess as the polish soaked in more.

The next day I took a clean paper towel and buffed the shoes. I was worried the polish would come right off again, but it didn't. It just buffed to a nice shine. I replaced the laces with darker brown and threaded a fake key on one to see how I like it (I don't; I'll probably replace it with something else eventually). I was going to glue something to the shoes themselves to make them more steampunk, but so far I haven't found anything that I like well enough. But I think they look good as they are.

They're going to kill my feet, but I'll look stylish.

How I turned my garage into a steampunk workshop without going broke, going crazy, or having nowhere to put my car.

Sunday, June 30, 2013

Sunday, June 23, 2013

Petticoat Practice

I found an excellent tutorial on making a tiered petticoat at The AntiCraft, and decided to use some cheap ($3 a yard) cotton eyelet fabric to practice.

I had six yards of the fabric, which was good because the bottom tier of the petticoat had to be cut from the decorative-hemmed bottom of the cloth and I needed six yards of that. Yes, six yards around the bottom of this piece. The middle tier is three yards around, the top tier is a yard and a half around at the bottom.

How does this work, you ask? Ruffles! Not the kind you eat with dip, unfortunately, but the kind that take for-freaking-ever to make, especially when your cat comes in halfway through smelling of skunk (a bottle of hydrogen peroxide, a quarter cup of baking soda, and a spoonful of dishwashing liquid, mix it up and wash your cat with it, it works like a charm, rinse with warm water and dry your cat as thoroughly as you can with towels because cats get cold really easily).

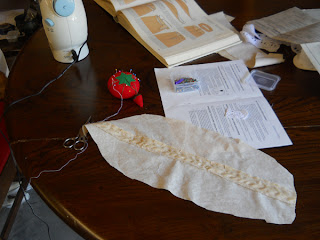

Basically, to make a ruffle you baste the top edge of the cloth piece loosely--I have to do this by hand since my sewing machine only does the one stitch. Then you pin the upper edges of the cloth to be ruffled to the bottom edge of the middle tier piece, pull on the basting thread so that the cloth bunches up, and distribute the ruffled bunches evenly and pin them in place. See in the picture below how nice and even the ruffles in the nearer half of the piece are compared to the farther half? I'd just finished the first half and hadn't started on the second.

Then you sew the pieces together. Now, if you're me and you're sloppy and you weren't thinking it through (maybe because you were distracted by a skunky cat), you pinned the cloth wrong so that there's a raw edge on the outside as well as the inside. It's okay, though. This is practice and no one should see anything but a glimpse of ruffle of a petticoat anyway.

Once that step is done, you get to do it again.

And finally, it's finished. And it doesn't look half-bad, although the tension seems to have already messed up on my sewing machine. Sewing machines are a mixed blessing: on the one hand, it took me hardly any time to actually sew the seams of this project (the ruffling took forever, but it always does); on the other hand, when a sewing machine's tension starts messing up, in my admittedly limited experience there is nothing you can do to fix it and the machine eventually becomes unusable.

I had six yards of the fabric, which was good because the bottom tier of the petticoat had to be cut from the decorative-hemmed bottom of the cloth and I needed six yards of that. Yes, six yards around the bottom of this piece. The middle tier is three yards around, the top tier is a yard and a half around at the bottom.

How does this work, you ask? Ruffles! Not the kind you eat with dip, unfortunately, but the kind that take for-freaking-ever to make, especially when your cat comes in halfway through smelling of skunk (a bottle of hydrogen peroxide, a quarter cup of baking soda, and a spoonful of dishwashing liquid, mix it up and wash your cat with it, it works like a charm, rinse with warm water and dry your cat as thoroughly as you can with towels because cats get cold really easily).

Basically, to make a ruffle you baste the top edge of the cloth piece loosely--I have to do this by hand since my sewing machine only does the one stitch. Then you pin the upper edges of the cloth to be ruffled to the bottom edge of the middle tier piece, pull on the basting thread so that the cloth bunches up, and distribute the ruffled bunches evenly and pin them in place. See in the picture below how nice and even the ruffles in the nearer half of the piece are compared to the farther half? I'd just finished the first half and hadn't started on the second.

Then you sew the pieces together. Now, if you're me and you're sloppy and you weren't thinking it through (maybe because you were distracted by a skunky cat), you pinned the cloth wrong so that there's a raw edge on the outside as well as the inside. It's okay, though. This is practice and no one should see anything but a glimpse of ruffle of a petticoat anyway.

Once that step is done, you get to do it again.

And finally, it's finished. And it doesn't look half-bad, although the tension seems to have already messed up on my sewing machine. Sewing machines are a mixed blessing: on the one hand, it took me hardly any time to actually sew the seams of this project (the ruffling took forever, but it always does); on the other hand, when a sewing machine's tension starts messing up, in my admittedly limited experience there is nothing you can do to fix it and the machine eventually becomes unusable.

Sunday, June 16, 2013

Owl Goggles

I hadn't planned to add so many feathers. I'm still not completely happy with them, and of course I still need to make a strap. And they won't sit on the brim of my awesome hat so I'll have to figure out some other way to display them that doesn't involve wearing them. But here they are, my very first pair of goggles, and a pair of the original welding goggles they started life as:

For those of you who are interested in making your own, it's a lot easier than I thought it would be. My first step was to remove the original strap, the plastic piece over the chain connecting the eyepieces, and remove the lenses (the eyepieces unscrew so you can remove them easily). Then I spraypainted them copper, making sure to get all the surfaces including the chain, and let them dry overnight.

Once they were dry, I put the lenses back in and adjusted the chain so that the goggles fit me. You can move the chain while the eyepieces are unscrewed; trim off excess so the ends won't gouge you in the eyeball. That would be pretty ironic if your eye protection blinded you. I noticed that there were two round pieces on the sides of the goggles, attached with a plastic pin through a hole. I have no idea what these are for, but I removed them and set them aside.

At this point I wasn't sure what to do. I had planned on painting decorations on the sides and then gluing some feathers on, and then I figured I'd be done. But they looked kind of boring, and I have all this leather scrap. I idly picked up a piece of pliable brown leather and wrapped it around the edge of an eyepiece.

It looked amazing! So I got out the glue, Gem-Tac, and put a line of it along the straight edge of the leather (on the wrong side, of course). I separated the eyepieces (took the chain off) so I could handle them more easily. Then I wrapped the leather around the edge of the eyepiece, leaving a small gap for the chain, tugging and stretching the leather to make it fit snugly over the plastic.

Gem-Tac turned out to be perfect for this kind of project. It starts to dry quickly so it held the leather in place as I worked, but it doesn't dry crazy fast like epoxy or superglue, so I could make adjustments after a few minutes if the leather wasn't quite where I wanted it.

Then I wrapped the leather around to the inside of the eyepiece. I didn't try to cover the inside completely and I did a messy job, but keep in mind that at this point I still didn't think the leather was going to actually work at all. I trimmed and cut notches as necessary to make it snug.

When I finished, I was blown away by how good it looked.

I put the chain back in place before the glue had completely set--I was worried I might have glued the lenses to the eyepieces and wouldn't be able to open them later. I also cut a piece of leather and glued it in place around the chain. Then I noticed the plastic pieces I'd removed earlier. I used my awl to poke holes in the leather so I could put the pieces back.

Then I took a break and ran to the store, and while I was gone I picked up some little brass acorn nuts at Lowe's. I was going to buy two dozen, since each eyepiece has a dozen spaces, but they're too damn expensive--almost $2.50 for four. I bought one dozen instead (if I were going to make a lot of goggles, I'd buy the acorn nuts in bulk, maybe from here). When I got them home, though, they looked awfully shiny. I set them out on a piece of cardboard and gave them one quick spritz of copper spraypaint--I didn't try to cover them completely, I just wanted to dim the shininess a bit. I let it dry overnight, then in the morning glued them on along with some other deco.

Next I considered what to do about a headstrap. Saturday I'd made the rounds of thrift shops and got two black leather purses (one for 99 cents and the other, a Liz Claiborne bag, for $1.50. Damn!), but both had straps that were a tad too wide. Plus the black leather looked funny next to the brown leather and copper/brass. So I decided to make a strap from leather scraps, but I wanted it to be a bit wider than the original strap. To solve the problem of getting a wider strap through the premade plastic gaps, I decided to attach loops with D-rings, to which I could attach a wider strap. As it happens, I had two D-rings of the right size that came off one of the purses, so I cut two pieces of thicker leather--in fact, I used the thickest, sturdiest leather I had, the same kind I used last week for my lawnmower handlebar grips.

Getting the straps through the little holes, which I had covered with leather and glue, was not easy. I used an X-acto knife to open up the gaps, then cut each leather strap at an angle. I used the awl to help cram the tip of the angle-cut end through the gap. As soon as I could grip it on the other side with needle-nosed pliers, I was able to pull it through. Then I trimmed the end straight, put the D-ring on, and glued it. For extra strength I also put a few stitches through the leather. I did a piss-poor job of it since I couldn't get the awl to go through all three thicknesses at the correct angle, and ended up using the needle-nosed pliers to force the needle through. KIDS, DON'T EVER DO THIS. It's dangerous! Not only are needles not meant for that sort of pressure and could break, sending a very sharp piece of metal into your eyeball (see irony, above), it's really easy to stab yourself in the finger like I did.

(Incidentally, a good thing to trim leather with is a wire cutter. Works better than scissors.)

Anyway, I got it finished and decided to wait on the strap itself until I can order some things I can't get locally. I almost declared myself finished. Then I remembered I'm going to DragonCon dressed inexplicably like a steampunk owl, which meant I had to add feathers. I probably should have just left well alone, I don't know. I could have created a lady naturalist persona and been perfectly happy, but noooo, I had to stick feathers on everything.

As I said earlier, I never intended to add many. I used pheasant feathers, which looked most owl-like of all the feathers I'd bought (I also have guinea hen, chicken, and turkey feathers). I chose three for each eyepiece, hampered a bit by the light but pleasant breeze blowing through the garage from the open doors. Then I held my breath, because I was about to do something irreversible. I put a triangle of glue on the edge of the first lens, thereby permanently gluing them closed. Then I pressed the feathers in place, arranged them carefully so they'd make a bird-of-prey frown, and held them there until the glue dried enough that I could let go. Then I did the same to the other lens.

And then I realized I'd RUINED MY GOGGLES, because I overlooked the fact that the eyepieces were sitting on a flat surface and not at the same angle they'd be when worn. You know that little scene in WALL*E when Wall-E wakes up and comes back to himself, and he adjusts his eyes until they're at just the right angle? Well, when I held my goggles up to my face, the angle of the feathers changed from fierce bird-of-prey frown to an anxious Wall-E expression.

I had to add more feathers. Then the goggles looked unbalanced, so I had to add a few feathers at the bottom too. They're more feathery than I wanted, but they also have a definitely owlish look, so maybe I'll get used to them.

I realized something while I was working, though. Back in April when I started this steampunk-my-garage project, all I really wanted was a space where I could work on crafts without making a mess in the house or running out of room. Well, I succeeded. Maybe the garage isn't as steampunky as I'd like--I can't afford to do more with it at this point--but I've got an awesome workspace.

For those of you who are interested in making your own, it's a lot easier than I thought it would be. My first step was to remove the original strap, the plastic piece over the chain connecting the eyepieces, and remove the lenses (the eyepieces unscrew so you can remove them easily). Then I spraypainted them copper, making sure to get all the surfaces including the chain, and let them dry overnight.

Once they were dry, I put the lenses back in and adjusted the chain so that the goggles fit me. You can move the chain while the eyepieces are unscrewed; trim off excess so the ends won't gouge you in the eyeball. That would be pretty ironic if your eye protection blinded you. I noticed that there were two round pieces on the sides of the goggles, attached with a plastic pin through a hole. I have no idea what these are for, but I removed them and set them aside.

At this point I wasn't sure what to do. I had planned on painting decorations on the sides and then gluing some feathers on, and then I figured I'd be done. But they looked kind of boring, and I have all this leather scrap. I idly picked up a piece of pliable brown leather and wrapped it around the edge of an eyepiece.

It looked amazing! So I got out the glue, Gem-Tac, and put a line of it along the straight edge of the leather (on the wrong side, of course). I separated the eyepieces (took the chain off) so I could handle them more easily. Then I wrapped the leather around the edge of the eyepiece, leaving a small gap for the chain, tugging and stretching the leather to make it fit snugly over the plastic.

Gem-Tac turned out to be perfect for this kind of project. It starts to dry quickly so it held the leather in place as I worked, but it doesn't dry crazy fast like epoxy or superglue, so I could make adjustments after a few minutes if the leather wasn't quite where I wanted it.

Then I wrapped the leather around to the inside of the eyepiece. I didn't try to cover the inside completely and I did a messy job, but keep in mind that at this point I still didn't think the leather was going to actually work at all. I trimmed and cut notches as necessary to make it snug.

When I finished, I was blown away by how good it looked.

I put the chain back in place before the glue had completely set--I was worried I might have glued the lenses to the eyepieces and wouldn't be able to open them later. I also cut a piece of leather and glued it in place around the chain. Then I noticed the plastic pieces I'd removed earlier. I used my awl to poke holes in the leather so I could put the pieces back.

Then I took a break and ran to the store, and while I was gone I picked up some little brass acorn nuts at Lowe's. I was going to buy two dozen, since each eyepiece has a dozen spaces, but they're too damn expensive--almost $2.50 for four. I bought one dozen instead (if I were going to make a lot of goggles, I'd buy the acorn nuts in bulk, maybe from here). When I got them home, though, they looked awfully shiny. I set them out on a piece of cardboard and gave them one quick spritz of copper spraypaint--I didn't try to cover them completely, I just wanted to dim the shininess a bit. I let it dry overnight, then in the morning glued them on along with some other deco.

Next I considered what to do about a headstrap. Saturday I'd made the rounds of thrift shops and got two black leather purses (one for 99 cents and the other, a Liz Claiborne bag, for $1.50. Damn!), but both had straps that were a tad too wide. Plus the black leather looked funny next to the brown leather and copper/brass. So I decided to make a strap from leather scraps, but I wanted it to be a bit wider than the original strap. To solve the problem of getting a wider strap through the premade plastic gaps, I decided to attach loops with D-rings, to which I could attach a wider strap. As it happens, I had two D-rings of the right size that came off one of the purses, so I cut two pieces of thicker leather--in fact, I used the thickest, sturdiest leather I had, the same kind I used last week for my lawnmower handlebar grips.

Getting the straps through the little holes, which I had covered with leather and glue, was not easy. I used an X-acto knife to open up the gaps, then cut each leather strap at an angle. I used the awl to help cram the tip of the angle-cut end through the gap. As soon as I could grip it on the other side with needle-nosed pliers, I was able to pull it through. Then I trimmed the end straight, put the D-ring on, and glued it. For extra strength I also put a few stitches through the leather. I did a piss-poor job of it since I couldn't get the awl to go through all three thicknesses at the correct angle, and ended up using the needle-nosed pliers to force the needle through. KIDS, DON'T EVER DO THIS. It's dangerous! Not only are needles not meant for that sort of pressure and could break, sending a very sharp piece of metal into your eyeball (see irony, above), it's really easy to stab yourself in the finger like I did.

(Incidentally, a good thing to trim leather with is a wire cutter. Works better than scissors.)

Anyway, I got it finished and decided to wait on the strap itself until I can order some things I can't get locally. I almost declared myself finished. Then I remembered I'm going to DragonCon dressed inexplicably like a steampunk owl, which meant I had to add feathers. I probably should have just left well alone, I don't know. I could have created a lady naturalist persona and been perfectly happy, but noooo, I had to stick feathers on everything.

As I said earlier, I never intended to add many. I used pheasant feathers, which looked most owl-like of all the feathers I'd bought (I also have guinea hen, chicken, and turkey feathers). I chose three for each eyepiece, hampered a bit by the light but pleasant breeze blowing through the garage from the open doors. Then I held my breath, because I was about to do something irreversible. I put a triangle of glue on the edge of the first lens, thereby permanently gluing them closed. Then I pressed the feathers in place, arranged them carefully so they'd make a bird-of-prey frown, and held them there until the glue dried enough that I could let go. Then I did the same to the other lens.

And then I realized I'd RUINED MY GOGGLES, because I overlooked the fact that the eyepieces were sitting on a flat surface and not at the same angle they'd be when worn. You know that little scene in WALL*E when Wall-E wakes up and comes back to himself, and he adjusts his eyes until they're at just the right angle? Well, when I held my goggles up to my face, the angle of the feathers changed from fierce bird-of-prey frown to an anxious Wall-E expression.

I had to add more feathers. Then the goggles looked unbalanced, so I had to add a few feathers at the bottom too. They're more feathery than I wanted, but they also have a definitely owlish look, so maybe I'll get used to them.

I realized something while I was working, though. Back in April when I started this steampunk-my-garage project, all I really wanted was a space where I could work on crafts without making a mess in the house or running out of room. Well, I succeeded. Maybe the garage isn't as steampunky as I'd like--I can't afford to do more with it at this point--but I've got an awesome workspace.

Saturday, June 15, 2013

Hat

I've been working on a pair of goggles--they are looking amazing, and hopefully I can finish them tomorrow--so I don't have anything to post today. So here is my awesome new hat. It's supposed to be crushable, but if anyone tries to crush my hat I will cut them.

I got it here. Here I am wearing it, a blurry pic that unsettles me since it looks like I'm staring into my bedroom at myself from inside the mirror. Also I see I didn't make my bed the other day. Also I see I look silly wearing the hat but I don't care, I love it ferociously. Also it is not a fedora, I don't even want to talk about fedoras. Also my hands look really huge in that pic because they were so close to the mirror, I don't actually look like Wreck-It Ralph ordinarily.

I was going to mod the hat, but I adore it so much I can't bear to ruin it by accident. All I did was yank out the feather it came with and replace it with a probably-owl feather I found a few weeks ago while hiking, which I attached with the merest drop of glue. (The pic is small because I had to take it with my phone since my camera inexplicably refused to focus. I don't yet know how to get pix off my phone to my computer without posting them to Twitter first and then saving the pic from Twitter.)

I got it here. Here I am wearing it, a blurry pic that unsettles me since it looks like I'm staring into my bedroom at myself from inside the mirror. Also I see I didn't make my bed the other day. Also I see I look silly wearing the hat but I don't care, I love it ferociously. Also it is not a fedora, I don't even want to talk about fedoras. Also my hands look really huge in that pic because they were so close to the mirror, I don't actually look like Wreck-It Ralph ordinarily.

I was going to mod the hat, but I adore it so much I can't bear to ruin it by accident. All I did was yank out the feather it came with and replace it with a probably-owl feather I found a few weeks ago while hiking, which I attached with the merest drop of glue. (The pic is small because I had to take it with my phone since my camera inexplicably refused to focus. I don't yet know how to get pix off my phone to my computer without posting them to Twitter first and then saving the pic from Twitter.)

Sunday, June 9, 2013

Leather lawnmower grips

I'm proud of myself. I got this project done start to finish this afternoon, something I'd been planning to do for months.

This is my lawnmower, before I worked on it (that's an old picture, obviously; I forgot to take a new before picture). I've had it about three years now and really like it. Today I had just started mowing the lawn when a storm moved in fast; I hurried into the garage just as the sky opened up, so I was stuck there for a while unless I wanted to get wet. Then I realized I had everything I needed to try replacing the torn-up sponge handlebar grips with leather.

This is the tutorial I read originally and wanted to try. I couldn't find anything that resembled what that guy calls cotton tape, though. Eventually I gave up looking. But the other day I was in the Dollar General, poking around so it wouldn't look like I'd only really come in to buy a candy bar, and I found some of that rubbery stuff they sell for putting in the bottom of drawers.

Wait, I'm going to do this as a proper tutorial because the project turned out so well.

YOU WILL NEED: some fairly thick leather (most big craft stores sell bags of leather scrap for about $5 each), that rubbery stuff that goes in the bottom of drawers, embroidery needles (they're sharp but have big eyes JUST LIKE ME), upholstery thread or other strong thread, cheap scissors don't use your good scissors what is wrong with you (or an X-acto knife or rotary blade), awl. Not pictured: awl.

The drawer liner goes first, giving the grips some cushion and acting as a non-slip surface. Figure out what size you need and cut two pieces. I used masking tape to hold it in place while I wrapped each piece around the handlebar. I made my pieces long enough to wrap two or three times. Wrap firmly but don't be obsessive about it--this stuff stretches. Once it's wrapped, hold it in place with another piece of masking tape.

Now sew the drawer liner in place. I used a blanket stitch but whatever you want to use will work. No one will see this part. Make sure to pick up all the layers when stitching; you want to feel that needle slide off the metal when you stitch. Knot securely when you're done.

Next cut a piece of leather for each grip, making it just big enough to wrap around but not overlap itself. It's better to cut the piece a tiny bit too small than too big. Leather stretches and you can pull the ends together if you need to, but if it's too big it'll look messy. I used a scrap piece of drawer liner to measure what size piece I needed because it's a lot easier to cut. Then I used that piece as a template, placed it on the back side of the leather, and used tailor's chalk (what I had on hand; anything will work) to mark out the pieces. Then I used cheap scissors to cut the leather. I had to trim a bit to get the pieces just right, holding them onto the handlebars to see how well they fit before I put them in place. This is worth taking your time over.

Now you need an awl. As it happens I do have an awl, and I'm so pleased I finally needed it for something. I didn't measure this part, just eyeballed it, because I'm not obsessive about detail and I like stuff to look sort of homemade and organic. Also I was already getting bored. Just make sure you put the same number of holes in each long side and that they have about the same spacing. After I did one side, I folded the top over to use as a guide for the other side. I still had to add a hole while sewing later.

Now go over to that other guy's tutorial and read it, because he makes it way clearer than I do and also he did a better job with his grips. Basically, you have a very long (about a yard) piece of thread with a needle at each end, and you use those needles to seam the grips just like lacing a tennis shoe. I used a rubber band to keep the leather in place while I was sewing, so I would have both hands free. As you complete each new pair of stitches, pull the previous pair good and tight. You don't want any loose threads that could snag on anything and snap later.

Doesn't that look good? I'm so proud of myself. They're nice and comfortable too.

By the time I'd finished, it had stopped raining, so I took the mower into the driveway and used copper spraypaint to paint the orange discs on the sides of the wheels. The orange still shows through but it looks a lot better than it did. I'm very pleased with the result!

Of course I still need to mow the lawn.

This is my lawnmower, before I worked on it (that's an old picture, obviously; I forgot to take a new before picture). I've had it about three years now and really like it. Today I had just started mowing the lawn when a storm moved in fast; I hurried into the garage just as the sky opened up, so I was stuck there for a while unless I wanted to get wet. Then I realized I had everything I needed to try replacing the torn-up sponge handlebar grips with leather.

This is the tutorial I read originally and wanted to try. I couldn't find anything that resembled what that guy calls cotton tape, though. Eventually I gave up looking. But the other day I was in the Dollar General, poking around so it wouldn't look like I'd only really come in to buy a candy bar, and I found some of that rubbery stuff they sell for putting in the bottom of drawers.

Wait, I'm going to do this as a proper tutorial because the project turned out so well.

YOU WILL NEED: some fairly thick leather (most big craft stores sell bags of leather scrap for about $5 each), that rubbery stuff that goes in the bottom of drawers, embroidery needles (they're sharp but have big eyes JUST LIKE ME), upholstery thread or other strong thread, cheap scissors don't use your good scissors what is wrong with you (or an X-acto knife or rotary blade), awl. Not pictured: awl.

The drawer liner goes first, giving the grips some cushion and acting as a non-slip surface. Figure out what size you need and cut two pieces. I used masking tape to hold it in place while I wrapped each piece around the handlebar. I made my pieces long enough to wrap two or three times. Wrap firmly but don't be obsessive about it--this stuff stretches. Once it's wrapped, hold it in place with another piece of masking tape.

Now sew the drawer liner in place. I used a blanket stitch but whatever you want to use will work. No one will see this part. Make sure to pick up all the layers when stitching; you want to feel that needle slide off the metal when you stitch. Knot securely when you're done.

Next cut a piece of leather for each grip, making it just big enough to wrap around but not overlap itself. It's better to cut the piece a tiny bit too small than too big. Leather stretches and you can pull the ends together if you need to, but if it's too big it'll look messy. I used a scrap piece of drawer liner to measure what size piece I needed because it's a lot easier to cut. Then I used that piece as a template, placed it on the back side of the leather, and used tailor's chalk (what I had on hand; anything will work) to mark out the pieces. Then I used cheap scissors to cut the leather. I had to trim a bit to get the pieces just right, holding them onto the handlebars to see how well they fit before I put them in place. This is worth taking your time over.

Now you need an awl. As it happens I do have an awl, and I'm so pleased I finally needed it for something. I didn't measure this part, just eyeballed it, because I'm not obsessive about detail and I like stuff to look sort of homemade and organic. Also I was already getting bored. Just make sure you put the same number of holes in each long side and that they have about the same spacing. After I did one side, I folded the top over to use as a guide for the other side. I still had to add a hole while sewing later.

Now go over to that other guy's tutorial and read it, because he makes it way clearer than I do and also he did a better job with his grips. Basically, you have a very long (about a yard) piece of thread with a needle at each end, and you use those needles to seam the grips just like lacing a tennis shoe. I used a rubber band to keep the leather in place while I was sewing, so I would have both hands free. As you complete each new pair of stitches, pull the previous pair good and tight. You don't want any loose threads that could snag on anything and snap later.

Doesn't that look good? I'm so proud of myself. They're nice and comfortable too.

By the time I'd finished, it had stopped raining, so I took the mower into the driveway and used copper spraypaint to paint the orange discs on the sides of the wheels. The orange still shows through but it looks a lot better than it did. I'm very pleased with the result!

Of course I still need to mow the lawn.

Saturday, June 8, 2013

Bloomers, take two

I believe these are technically pantaloons. Apparently bloomers have gathered cuffs, pantaloons don't. Either way, I've finished them and can move on to something more interesting.

Last weekend I got the legs and cuffs done and sewed the front center seam. The other evening I got online and did a search for help on that particular Simplicity pattern in hopes of some tips for making the waistband. I also was hoping for some clarification on the pattern's general directions, because there seemed to be a step or two missing. What I found, though, was that the steps I thought were missing--namely, when/how to sew up the crotch--weren't missing at all. The pattern is supposed to make authentically old-timey pantaloons, and in the old days women wore crotchless underthings.

When you think about it, it makes sense in the days of chamber pots. That doesn't mean I have to wear them that way. So I promptly ran a seam right along the crotch.

At that point I tried the pantaloons on, mostly to see if I could fold the waist hem over to make a casing and use elastic instead of making a waistband. There was, but I discovered a problem with the pattern. Maybe it had something to do with me sewing up that crotch seam, but I suspect it's something to do with the way the pattern's made. I was using the size 10 pattern and it fit nicely in the legs, but the front and back seemed to be intended for someone shaped like a ball. I know I don't use all the ease Simplicity builds into its patterns, but this was more than just an inch or two added from seams. Even gathering and pleating wasn't going to take care of the problem, and when I turned around and looked in the mirror, the butt was poofy and horrible. I looked like I was supposed to wear a really thick diaper under the pantaloons.

In a fit of fury, and since I certainly couldn't wear the pantaloons as they were, I grabbed some pins and used them to mark most of the excess. Then I pulled off the pantaloons and, without measuring or even trying to make it even, I cut a big chunk of cloth out of the back. Then I seamed it, sewed a casing and threaded elastic through, and tried them on again.

Above: that's the initial strip I cut out. I cut more after that but that was the biggest piece. I wish now I'd been even braver and cut another inch or two, plus I could have done the same in the front.

They fit. They're still baggy in the butt and stomach, and the leg fabric pulls in a weird way (when they're hanging up they look like they're made for a super bowlegged lady), but they look fab from the knee down and that's all anyone will ever see. I threaded a brown ribbon through the cuff eyelets, which looks awesome.

Here's me wearing them, with an old nightgown pressed into service as a chemise so you can't see how weird the pantaloons look around the waist and crotch. They're really unbecoming.

(My legs look really fat in that picture, but in the pictures where my legs look better the pantaloons weren't all that visible. That's a scab on my shin, by the way, from the other day when I tripped on the porch. And yes, I am wearing pirate socks, why do you ask?)

I started making a detachable feather trim for the cuffs, white fluffy feathers sewed to a white ribbon (chicken feathers; I bought a bunch of them and it looks like I've been on a plucking spree--my house is adrift in bits of fluff). But the trim looks superfluous with the crochet trim I've already got in place, and if I fold the trim up to pin the feather trim in place, they're not nearly as cute. So I'll use the feathers for something else.

Last weekend I got the legs and cuffs done and sewed the front center seam. The other evening I got online and did a search for help on that particular Simplicity pattern in hopes of some tips for making the waistband. I also was hoping for some clarification on the pattern's general directions, because there seemed to be a step or two missing. What I found, though, was that the steps I thought were missing--namely, when/how to sew up the crotch--weren't missing at all. The pattern is supposed to make authentically old-timey pantaloons, and in the old days women wore crotchless underthings.

When you think about it, it makes sense in the days of chamber pots. That doesn't mean I have to wear them that way. So I promptly ran a seam right along the crotch.

At that point I tried the pantaloons on, mostly to see if I could fold the waist hem over to make a casing and use elastic instead of making a waistband. There was, but I discovered a problem with the pattern. Maybe it had something to do with me sewing up that crotch seam, but I suspect it's something to do with the way the pattern's made. I was using the size 10 pattern and it fit nicely in the legs, but the front and back seemed to be intended for someone shaped like a ball. I know I don't use all the ease Simplicity builds into its patterns, but this was more than just an inch or two added from seams. Even gathering and pleating wasn't going to take care of the problem, and when I turned around and looked in the mirror, the butt was poofy and horrible. I looked like I was supposed to wear a really thick diaper under the pantaloons.

In a fit of fury, and since I certainly couldn't wear the pantaloons as they were, I grabbed some pins and used them to mark most of the excess. Then I pulled off the pantaloons and, without measuring or even trying to make it even, I cut a big chunk of cloth out of the back. Then I seamed it, sewed a casing and threaded elastic through, and tried them on again.

Above: that's the initial strip I cut out. I cut more after that but that was the biggest piece. I wish now I'd been even braver and cut another inch or two, plus I could have done the same in the front.

They fit. They're still baggy in the butt and stomach, and the leg fabric pulls in a weird way (when they're hanging up they look like they're made for a super bowlegged lady), but they look fab from the knee down and that's all anyone will ever see. I threaded a brown ribbon through the cuff eyelets, which looks awesome.

Here's me wearing them, with an old nightgown pressed into service as a chemise so you can't see how weird the pantaloons look around the waist and crotch. They're really unbecoming.

(My legs look really fat in that picture, but in the pictures where my legs look better the pantaloons weren't all that visible. That's a scab on my shin, by the way, from the other day when I tripped on the porch. And yes, I am wearing pirate socks, why do you ask?)

I started making a detachable feather trim for the cuffs, white fluffy feathers sewed to a white ribbon (chicken feathers; I bought a bunch of them and it looks like I've been on a plucking spree--my house is adrift in bits of fluff). But the trim looks superfluous with the crochet trim I've already got in place, and if I fold the trim up to pin the feather trim in place, they're not nearly as cute. So I'll use the feathers for something else.

Sunday, June 2, 2013

The Sewing Machine

It's totally not steampunk, and it would take a lot of work to make it not look like a plastic toy, but it's saving me a lot of time. Yes, I bought a sewing machine. It cost me all of $20 and you can see how small it is. It does one thing: lockstitch, forward only. But that's all I need it for.

I also found a pattern for bloomers that I think will work a lot better than the simple patterns I've found for free online. It includes patterns for a chemise and corset too, so I think it's a good investment. I took a picture of it in front of the window so the light would stream in like a halo.

This is the fabric I have bought for my Dragon*Con outfit, although I won't know about the dark brown feather-print fabric and the light brown lace until I get my finished corset and can look at the colors together. But the yellow-and-white cloth is for my bloomers. If you look closely, you can see it has a swirly pattern sort of like white feathers, perfect for an owl-thing costume.

It's been a busy week for me, so I didn't get as much done on the bloomers as I'd like. I've also cut one corner already, on the cuffs. The pattern goes through a complicated method for removing the edging of gathered lace and sewing new gathers into it, and then doing something with eyelets--I read over it and thought, "The hell with this." I had some nice edging that's perfect for threading ribbons through to make gathers once the garment is finished, so I just sewed it on. I seamed it twice, once above the eyelets, once below, to make a sort of casing. My little sewing machine did quite well getting through the heavier edging. I thought it wouldn't at first--the thread kept snapping--but then I realized I hadn't rethreaded the machine properly. I fixed it and it was fine.

I've never made a waistband before, and that's my next step. I almost started tonight, but after reading the directions over several times I still can't figure out what I'm doing. I'll have to read up on waistbands in my sewing books. I gave up for the evening, since it was pouring rain anyway and I wanted to go inside, get into my pajamas, and read. So that's what I'm going to do.

I also found a pattern for bloomers that I think will work a lot better than the simple patterns I've found for free online. It includes patterns for a chemise and corset too, so I think it's a good investment. I took a picture of it in front of the window so the light would stream in like a halo.

This is the fabric I have bought for my Dragon*Con outfit, although I won't know about the dark brown feather-print fabric and the light brown lace until I get my finished corset and can look at the colors together. But the yellow-and-white cloth is for my bloomers. If you look closely, you can see it has a swirly pattern sort of like white feathers, perfect for an owl-thing costume.

It's been a busy week for me, so I didn't get as much done on the bloomers as I'd like. I've also cut one corner already, on the cuffs. The pattern goes through a complicated method for removing the edging of gathered lace and sewing new gathers into it, and then doing something with eyelets--I read over it and thought, "The hell with this." I had some nice edging that's perfect for threading ribbons through to make gathers once the garment is finished, so I just sewed it on. I seamed it twice, once above the eyelets, once below, to make a sort of casing. My little sewing machine did quite well getting through the heavier edging. I thought it wouldn't at first--the thread kept snapping--but then I realized I hadn't rethreaded the machine properly. I fixed it and it was fine.

I've never made a waistband before, and that's my next step. I almost started tonight, but after reading the directions over several times I still can't figure out what I'm doing. I'll have to read up on waistbands in my sewing books. I gave up for the evening, since it was pouring rain anyway and I wanted to go inside, get into my pajamas, and read. So that's what I'm going to do.

Subscribe to:

Posts (Atom)